Laser Metal Cutting Effective Accessories Application | Laser Engraving, Vinyl Cutter, UV Printer - GCC

Auxiliary gas is one of the inevitable elements of metal cutting. The appropriate auxiliary gas to go with the metallic material you work with helps reach optimum cutting effects. Through the assistance of auxiliary gas, the process of metal cutting is accelerated and the cross-section is bright and clear, reducing post processing time.

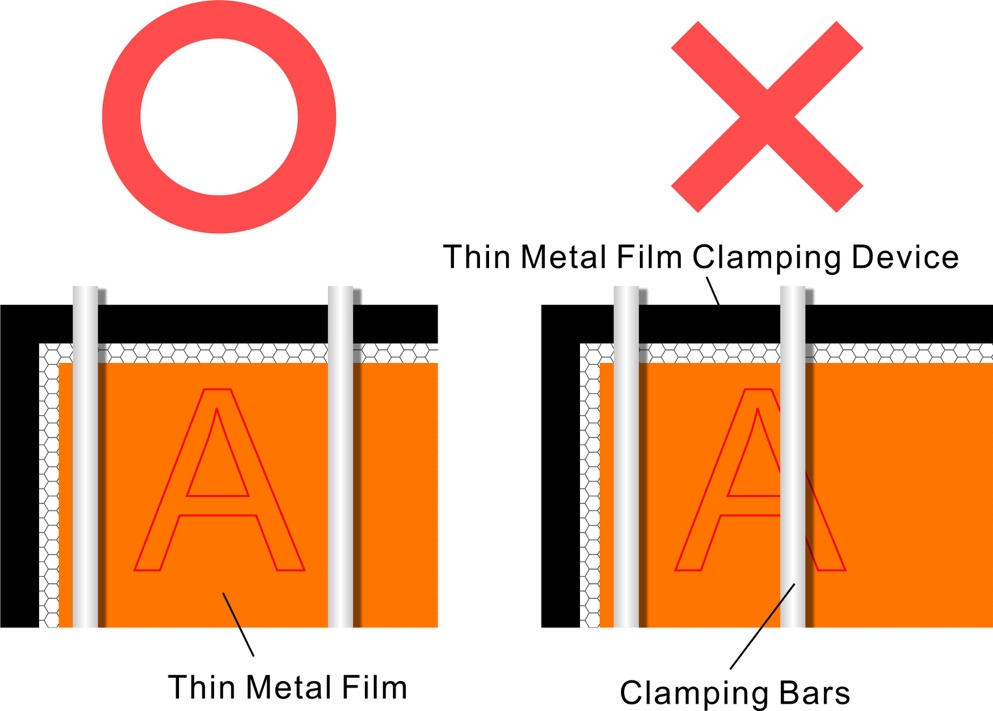

However, the disadvantage of gas, a crucial role in the process, is that the hyperbaric gas applied to the thin metal would cause metal vibration and thus deteriorate cutting quality. To tackle this problem, GCC LaserPro has launched the innovated Thin Metal Film Clamping Device. Stabilizing the thin metal to be processed, the Clamping Bars on the device help avoid metal vibration caused by auxiliary gas and minimize metal deformation during the cutting process, making the Thin Metal Film Clamping Device a top-notch helper.

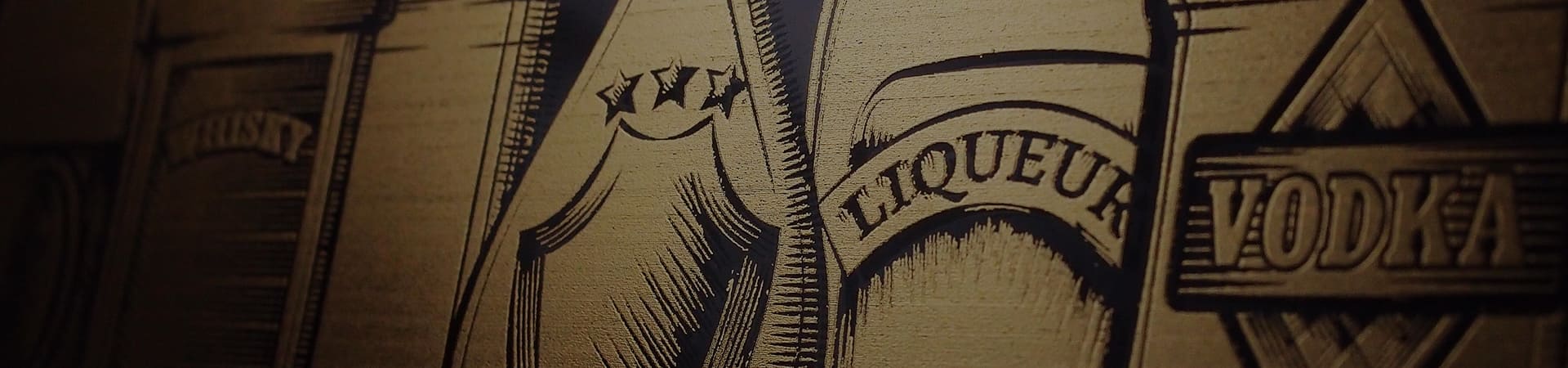

The GCC LaserPro Application Lab of the month presents you fine quality earrings created with GCC LaserPro FMC 280 through the assistance of the Thin Metal Film Clamping Device. Enjoy the wow effect of this amazing device with us now! Prepare to be impressed!

Material: 0.5mm Brass

Procedures:

Step 1. Place the Thin Metal Film Clamping Device on the worktop.

Step 2. Place the thin metallic material on the device and fix the metal with the Clamping Bars.

Step 3. Press "Autofocus" to automatically set the focal distance.

Step 4. Complete parameter setting and press "Start" to begin cutting.

Step 5. Sample is complete.

Suggested parameters:

| FMC 280 | |||||

| Speed | Power | DPI | PPI | Frequency | Air |

| 0.7 % | 100 % | 3000 | X | 100 | Nitrogen 100 psi |

*The parameters are for suggestions only and should be moderately adjusted accordingly.

Tips:

Please ensure the cutting object locates between the Clamping Bars before processing to allow sufficient cutting area to avoid material waste.