Embossing seal with laser engraving | Laser Engraving, Vinyl Cutter, UV Printer - GCC

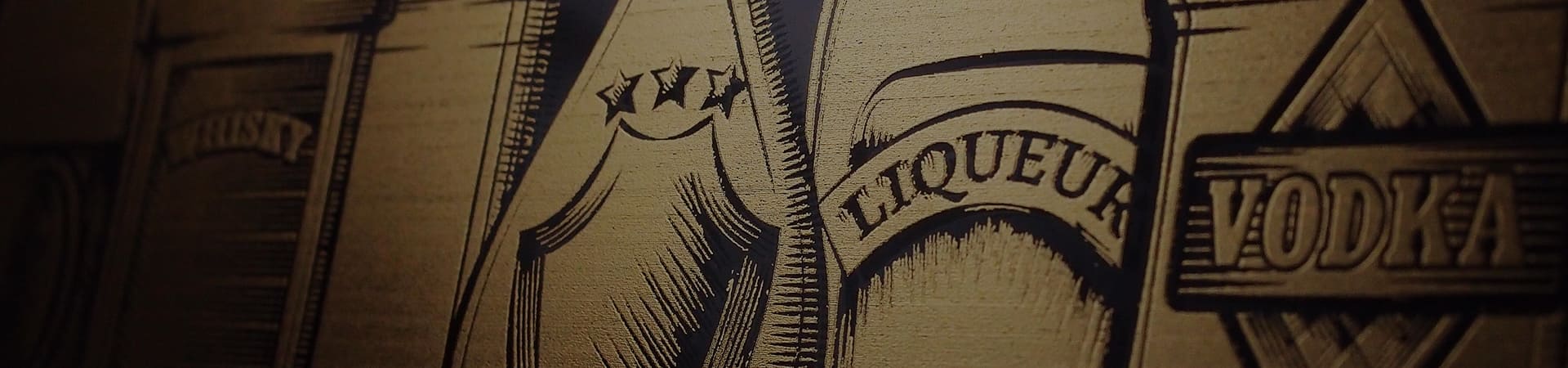

Embossing sealing is a traditional imprinting technique which still exists in the sealing of various types of paper documents, contracts, certificates, tickets and other materials. The imprint surface of conventional seals is mostly made from copper to achieve great hardness and durability, increasing the cost of seals as copper is an expensive material. As improvements on plastic ingredients are made constantly, some plastic materials have come close to metal in terms of their hardness and flexibility. POM (Polyoxymethylene), a popular building material in recent years, for instance, is a type of hard plastic and is an ideal material for imprint surfaces.

The GCC LaserPro Application Lab of the month is going to create a portable embossing seal with POM. GCC LaserPro laser engravers ensure precise and stable power output, producing neat imprint surfaces that allow compact sealing, making every stamp a perfect one! Create your own personalized embossing seal with GCC LaserPro now!

Materials needed:

- Embossing seal

- 2mm POM Sheet

Processing procedure:

Step 1. Create an image through graphic design software with a concave and a convex side.

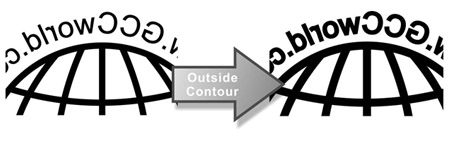

Step 2. PReduce the convex side by approximately 0.15~0.2mm using the Contour function.

Step 3. Send the file to the engraver.

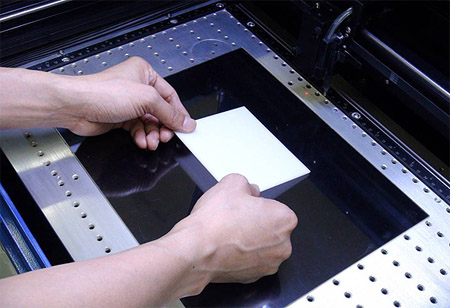

Step 4. Place POM on the working table of the engraver.

Step 5. Press "Auto Focus" to automatically set the focal distance.

Step 6. Press "Start" to begin processing.

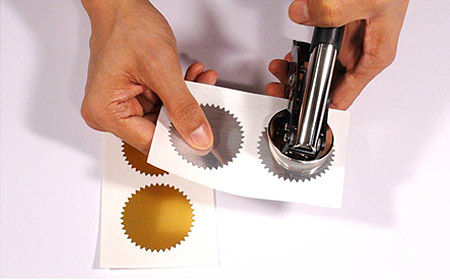

Step 7. Attach the sample created to an embosser.

Step 8. Imprint on the material.

Step 9. Stick embossed stickers on objects

Sample is complete.

Suggested parameters:

| C180II 30W | ||||

| Speed | Power | DPI | PPI | Other |

| 35 % | 100 % | 500 | 400 | Error Diffusion |

*The parameters are for suggestions only and should be moderately adjusted accordingly.

Tips:

- Before you start the job, please make sure the material is completely flat and even to avoid material waste caused by defocuses.

- Please make sure the contour line width is 0.15mm or above to avoid paper cracks when imprints are made.